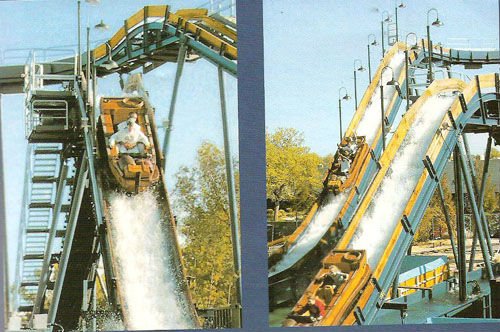

An on-ride photo was taken on the final drop and can be purchased from the photo store adjacent to the ride. During the final drop, riders reached speeds of up to 58 kilometres per hour (36 mph). At this point riders were 13 metres (43 ft) above ground. The track navigated the perimeter of the building before approaching the final drop. It then began the conveyor belt-powered lift hill to the top of the building. Once released by the control system, the ride turned around and ventured alongside the station of the ride before approaching the Sea World Theatre which was themed as a Viking's castle. This system ensured that the boats that were dispatched from the 2 parallel stations do not run into each other. When the boat left the load station it moved further forward toward the main channel before reaching a brake system. Each Viking-themed boat arranged riders inline in four rows. Riders boarded one of twenty-two, four-person boats. The station was made up of four platforms which allowed two boats to load as another two were unloading.

The queue crossed part of the ride's track and into the centre of the station. Riders joined the queue which began alongside the station of the ride. On 10 December 2016, the Viking's Revenge Flume Ride was confirmed to be permanently closed by Village Roadshow Theme Parks. Several components were removed from the ride during this period, and all signage was removed from the park. In November 2016, in the wake of a fatal incident at nearby park Dreamworld, which triggered safety audits in amusement parks across Queensland, the ride was closed indefinitely for extensive maintenance. In late 2012, the ride's course was rerouted to make way for the construction of the park's 2013 attraction, Storm Coaster, on the site of the former Bermuda Triangle ride. After a soft-opening in 1978, the ride officially opened in March 1979. The final cost of the ride turned out to be $350,000 - a fraction of what Arrow Dynamics wanted. He made several overseas trips to measure the dimensions of similar rides. John Menzies decided this price was too high and began constructing the ride in-house. American firm Arrow Dynamics was approached, however, they asked $1.5 million to construct it. They also offer customization options according to your tastes and preferences.In the late 1970s, Sea World set about adding a log flume to their park. This online shopping has a wide range of animatronic models that suits your needs and budget. If you want to keep up with the latest trends, visit for wholesale log flume ride. 3D printers, for instance, are commonly used nowadays to create log flume ride and molds, speeding up the process.Īnimatronic models have helped in leveling up the entertainment industry. Many technological advancements have enhanced the functionality of log flume ride throughout the years. The final log flume ride can follow instructions and move around using a remote control. Finally, insert a metal skeleton into the cast and link all the parts. After that, you need to dismantle the animatronic model into several pieces to help in improving the realism of the final output.

Such materials include fiberglass, resin, and rubber. The resources utilized will differ depending on the type of creature you are creating. The next step after molding involves casting. You can use the same mold if you need to make several log flume ride especially if they are of the same structure.

Log flume ride manufacturers skin#

After approval of the small model, the artist then proceeds to create a full-size log flume ride.They'll begin by shaping clay or another substance into the desired shape and then use sculpting tools to add details like skin texture and face features. First of all, an artist begins by drawing a concept and then create tiny models. However, the process for making each of them varies.

0 kommentar(er)

0 kommentar(er)